Tomato sauce is a versatile culinary staple enjoyed across the globe. In the UK, where demand for high-quality, locally-produced food continues to rise, understanding the process of tomato sauce production and storage is essential for both home cooks and food manufacturers. From crafting a traditional recipe to meeting stringent food production regulations, the journey of tomato sauce from farm to table is both art and science. This article explores how to make tomato sauce for sale, the best practices for storage, sterilization methods, required equipment, and the key regulations governing food production in the UK.

How to make tomato sauce for sale

Creating tomato sauce for commercial purposes requires more than just a great recipe. It starts with sourcing the freshest, ripest tomatoes to ensure a rich, natural flavort.

The process begins with washing and blanching the tomatoes to remove skins, followed by deseeding and cooking. Depending on the desired flavor profile, ingredients like garlic, onions, olive oil, and herbs are added during the cooking process. Consistency is achieved by blending or sieving the sauce to remove any remaining chunks.

Preservation is a critical factor in commercial production. To extend shelf life, many producers use natural preservatives such as citric acid or vinegar. Packaging the sauce in airtight jars or bottles under sterile conditions prevents contamination and ensures product safety.

Tomato sauce storage

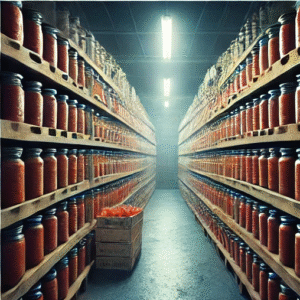

Proper storage is vital to maintaining the quality and safety of tomato sauce. For small-scale producers, cool, dark environments are ideal for storing bottled sauce, as exposure to light and heat can degrade flavor and color. Larger manufacturers often utilize climate-controlled storage facilities to maintain consistent temperature and humidity levels.

Refrigeration is necessary for sauces with lower acidity or those made without preservatives. Freezing is another option, particularly for homemade or small-batch productions, as it preserves the sauce for several months without compromising taste. However, care must be taken to use freezer-safe containers to prevent leaks and freezer burn.

For commercial operations, it’s essential to implement a robust inventory management system to track production dates and ensure products are sold within their optimal shelf life. Clear labeling with storage instructions and expiration dates is not only helpful for consumers but also a regulatory requirement in the UK.

How to sterilize tomato sauce

Sterilization is a cornerstone of tomato sauce production, especially when preparing the sauce for sale. It involves eliminating harmful bacteria, yeasts, and molds to ensure product safety and extend shelf life.

The most common sterilization method is heat treatment, often achieved through pasteurization or hot-filling. In pasteurization, the sauce is heated to a specific temperature, typically between 70°C and 85°C, for a set period. This kills most microorganisms without compromising the sauce’s flavor and texture.

For hot-filling, the sauce is poured into sterilized jars or bottles while still hot. The containers are then sealed immediately to create a vacuum effect that prevents contamination. Alternatively, pressure canning is used for low-acid sauces, where jars are placed in a pressure cooker to achieve higher sterilization temperatures.

Cleanliness is crucial throughout the process. All equipment and containers must be thoroughly washed and sterilized before use. Many producers rely on industrial-grade sterilizers or chemical sanitizing agents approved for food production to meet hygiene standards.

Tomato sauce equipment

Producing tomato sauce at scale requires specialized equipment. For small-batch operations, a high-quality blender or food processor, large cooking pots, and sieves are sufficient. However, scaling up production necessitates investing in industrial-grade machinery.

Key equipment includes:

- Tomato Washers and Sorters: Ensure that raw tomatoes are clean and free from debris.

- Peeling Machines: Speed up the removal of skins, especially for large quantities.

- Cooking Kettles: Designed for even heating and large-batch cooking.

- Blenders and Homogenizers: Ensure smooth consistency.

- Filling Machines: Automate the process of pouring sauce into jars or bottles.

- Labeling Machines: Apply labels efficiently and accurately.

For storage, producers often use stainless steel tanks with temperature controls, ensuring the sauce remains fresh before packaging. Choosing the right equipment not only improves efficiency but also helps maintain the highest quality standards.

Food production regulations

In the UK, tomato sauce producers must adhere to strict food production regulations to ensure consumer safety and product quality. The Food Standards Agency (FSA) oversees these regulations, which cover everything from ingredient sourcing to packaging and labeling.

Key regulatory considerations include:

- Hygiene Standards: All production facilities must comply with the UK’s food hygiene standards, which mandate regular cleaning, pest control, and staff training.

- Allergen Labeling: Producers must clearly label any allergens present in their products, such as celery or sulfites.

- Traceability: Ingredients must be traceable back to their source to ensure accountability in case of recalls.

- Nutritional Information: Labels must display accurate nutritional information, including calorie content, fat, and sugar levels.

- Packaging Requirements: All packaging materials must be food-safe and environmentally compliant, with many producers now opting for recyclable or biodegradable options.

- Licensing and Inspections: Commercial producers must obtain the necessary licenses and undergo regular inspections to verify compliance with UK food safety laws.

For new entrants to the market, consulting with a food safety expert or regulatory advisor can be invaluable. They can help navigate the complexities of UK food law and ensure all legal requirements are met, from production to sale.

Conclusion

Producing and storing tomato sauce in the UK involves a careful balance of culinary expertise and adherence to regulatory standards. By following best practices for preparation, storage, and sterilization, and investing in the right equipment, producers can create high-quality sauces that meet consumer expectations and comply with stringent food safety laws. Whether you are a small-scale artisan or a large manufacturer, understanding these processes is key to success in the competitive food industry.